|

|

UF chemists and engineers seek to capture more of the Sun's energy less expensivelyBy Michal Meyer Every hour, enough sunlight reaches the Earth to meet human’s energy needs for a year; yet solar energy accounts for just 0.015 percent of world electricity production. That’s because for more than half a century, solar has relied on expensive silicon-based photovoltaic cells that simply have not been able to compete with cheap fossil fuels. But just as oil, gas and coal are growing ever more scarce and expensive — economically, environmentally and politically — engineers and chemists at the University of Florida and elsewhere are developing a new generation of cheaper, lighter and more versatile solar cells. Photovoltaic cells are comprised of light-absorbing materials that generate a current of electricity when hit by sunlight. When photons of light strike a photovoltaic cell, some electrons in the material absorb that light energy and use it to break the bonds that keep them tied to their atom. As these electrons search for a new home in another atom, they generate energy that can be captured as electricity. Since the 1950s, the most common and most efficient material for producing photovoltaic cells has been silicon wafers, which, for most uses, convert about 20 percent of the sunlight that hits them into electricity. But this efficiency comes at a high manufacturing cost, including the cost of the bulky stands that must support the heavy arrays of cells. Now, UF researchers are pioneering methods for making a new breed of exceptionally thin and cheap organic solar cells whose lower efficiency might be offset by their lower cost. These scientists see a future where roof tiles and paint generate their own electricity, and even fabric can produce enough energy to run an iPod or a cell phone. “We can envision making huge sheets of photovoltaic cells that can be rolled up and taken out to the field and wired up,” says chemistry Professor Kirk Schanze. “They could also be used as a tent, or tiles in a roof that would be inexpensive and replaceable.”

Although plants have been turning the Sun’s bounty of light into plentiful energy since the dawn of time, only since the 1970s has carbon become a potential source of photovoltaic cells as scientists developed ways to force organic materials to generate current. Researchers were attracted to organic cells for their flexibility (unlike silicon, they bend rather than break under stress) and low cost. And while it’s unlikely organic solar cells will ever completely replace inorganic because of their lower energy efficiency and shorter lifespan, materials science Assistant Professor Jiangeng Xue isn’t giving up. “A conservative estimate is that 20-percent efficiency is reachable, and with better materials 30 percent will be possible,” he says, “but that doesn’t mean we can get that in the next couple of years. We need to find new materials and improve the device structure.” Efficiency, he adds, need reach only 6 to 8 percent for some commercial applications because lower production costs mean that even low efficiencies can still be cost effective. And Xue knows efficiency. While at Princeton University, he helped create what is to date the world’s most efficient organic solar cell. He also knows all the problems researchers face in making such cells efficient. “It’s related to the fundamental difference between organic and inorganic materials,” he says, pointing out that organic materials require two steps to create an electrical charge instead of converting the energy directly. In organics, the roving negative electron is coupled with a positively charged companion that cancels out its charge. That binding must be broken before the electron can do its work. Schanze and fellow chemistry Professor John Reynolds are working on solutions to such problems. Between them, the two have about 50 years of experience in the field, and they are at a university that has focused on photovoltaic research since the 1950s. UF mechanical engineering Professor Emeritus Erich Farber established the Solar Energy and Energy Conversion Laboratory (SEECL) on campus in 1954 and served as its director for 37 years. Farber was named to the Solar Hall of Fame in 1976 and the lab was named a historic landmark by the American Society of Mechanical Engineers in 2003. One of the things Schanze and Reynolds have discovered is that adding an inorganic material like metal to an organic solar cell forces the cell to work harder, producing more current for the same amount of sunlight. Adding small amounts of metals such as platinum to the organic solar cell helps electrons keep their light energy and stay out of the clutches of their positive traveling companions, making it more likely they will survive their trip through the material and produce electricity. To make polymers that generate electricity, the chemists mix materials with different molecular structures and energies. The different atomic structure of the two materials can be used to drive freed electrons where they need to go. Fine-tuning that energy difference is critical to making successful organic photovoltaic cells, which means making new materials with just the right properties. “We’re synthesizing new polymers, and we understand their properties through a number of chemical and physical characterization experiments,” says Reynolds. “Our group is not looking to make a practical solar cell, but to make materials with new and optimized properties that would make solar cells better.”

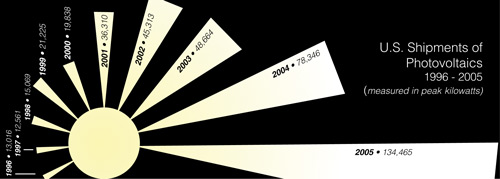

Solar SpectrumFrom infrared to ultraviolet, the Sun is bombarding the Earth’s surface with a much broader range of light energy than humans can see, yet today’s organic photovoltaic cells convert only visible light into electricity. By creating new polymers, the chemistry team aims to stretch the light-absorbing boundary into the near infrared, just below visible red light. Although near-infrared light has less energy than visible light, much more of it hits the Earth’s surface. Increasing efficiency by harnessing this untapped reservoir of low-energy light is high on the UF researchers’ to-do list. “Extending this light-absorbing boundary is critical to creating a commercial organic solar cell,” says Xue. Another researcher focusing on low-energy light is materials science Associate Professor Franky So. The approach is different, but the goal is the same: making as much use as possible of the light the Sun sends our way. So is focusing on carefully measured amounts of inorganic nanoparticles of lead selenide a thousand times thinner than a human hair to encourage the polymer to put more light to work in producing electricity. So can make his nanoparticles larger or smaller, depending on what kind of light he wants his material to absorb. The bigger the nanoparticle, the less light energy it traps, but the greater the amount of light. “One thing I’m exploring is the effect of shape and size, of making the nanoparticles into spheres, rods and even tetrapods,” says So. Adds Paul Holloway, professor of materials science and engineering: “Everyone is just beginning to understand nanoparticles.” Holloway, who works with Xue and So, puts his nanoparticles to different use. His dicadmium sulphide nanoparticles, with a bit of manganese and zinc added, produce bright yellow light when electricity is added. Now Holloway is trying a variation on his light-producing nanoparticle, so that when it is added to polymers it will turn into an electricity-producing nanoparticle that will help transport the electrons. While silicon solar panels can last decades, the longevity of organic solar cells remains untested. They will have to be protected from ultraviolet light, moisture and even air, all of which damage and degrade the organic materials. Here, the tried and tested technology of organic electronic displays provides guidance. Found in cell phones and car radios, these color displays contain the same basic materials as organic solar cells and give two to four years of continuous operation. And, argues Xue, lifespan might turn out to be not much of an issue. “For these organic solar panels, I don’t know if we need 25 years of lifetime, as the cost of these devices is so cheap,” says Xue. “We could use them for a few years and then throw them away. The installation costs will be very low because they are flexible.” Compared to silicon panels, which are heavy, brittle and easily broken, installation will be a snap. “You just need to roll it out and fix the edges,” says Xue. “It’s kind of simple.” Inorganic, But Still ThinA different route to the same goal of a light and efficient photovoltaic cell is through a material with the unlikely acronym of CIGS. Made up of a thin film of copper, indium, gallium and selenium, this light-absorbing inorganic material is remarkably versatile. “It’s a very robust and easy-to-handle material. It can be grown in many different ways, and it always comes back to similar properties,” says chemical engineering Professor Tim Anderson. The cost of making the CIGS film varies with temperature, so Anderson and colleagues Oscar Crisalle and Valentin Craciun are looking for ways to balance efficiency, which goes down as temperature goes down, with the cheaper production costs of lower temperatures. “To be truly accepted we have to reduce the cost of manufacturing,” says Anderson. “This means we have to reduce the time it takes to make the absorber material from 40 minutes to about two minutes.” Another way to reduce the overall cost of the CIGS photovoltaic cell is by increasing the efficiency of electron transport by reducing defects in the material that can trap electrons and stop their movement. This alone can increase efficiency from 9 percent to 12 percent. Anderson also has a solution to ultraviolet damage in organic cells. Placing one of his inorganic cells that absorbs ultraviolet light on top of an organic cell that absorbs visible light increases the range of light that can be captured and protects the organic cell from damage. Despite its low percentage, the amount of solar energy produced in the world has more than doubled since 2000, spurred by increased support from the Department of Energy and the commercial sector. “There’s no doubt that the promise of organic materials is not that far out, probably 20 to 25 years in terms of implementation,” says Schanze. For centuries we’ve been using solar energy stored up by plants over millions of years — in the form of coal and oil. The UF researchers hope to cut out the middleman and go directly to the source. “I think solar energy is the ultimate renewable energy,” says Anderson. “It’s basically capturing radiation from a nuclear reactor 93 million miles away.”

Timothy J. Anderson Paul H. Holloway John Reynolds Kirk Schanze Franky So Jiangeng Xue |